The Magic of Corn Seed Germination and Emergence

I think nearly every corn planter in Wisconsin was planting this past week. There are some wet areas in northeastern Wisconsin that have prevented planting, but a significant jump in planted acreage should be measured by USDA-NASS in next Monday’s progress report.

Now the magic begins when dry seed imbibes water and bare or brown fields turn greener every day across the landscape. The germination process and the success of the seed in emerging and establishing is key and the first yield component determined for the growing season.

Protected within the seed coat is an embryonic plant that remains dormant until germination is initiated by the physical process of imbibing water. The white starchy endosperm is the main energy source until the young seedling is established. After planting, water and oxygen are imbibed into the seed for 24-48 hours activating the growth hormones and enzymes. Starch is broken down supplying the embryo with energy for metabolism and cell division.

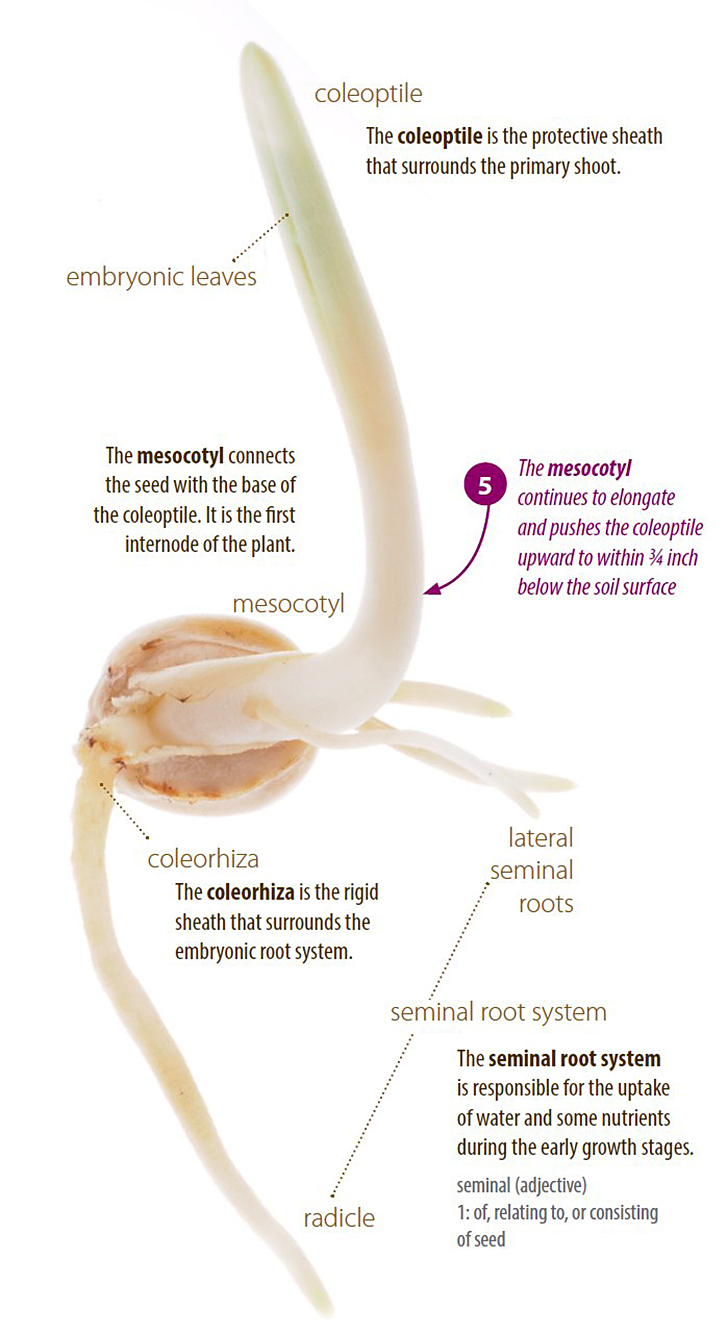

Within the embryo is a miniature corn plant that already has a primary shoot, leaves and root system protected by rigid sheaths called the coleoptile (above-ground) and coleorhiza (below-ground). The first structure to emerge from the seed is the radicle root, followed by the coleoptile and seminal roots.

Figure 1. Diagram of germinating corn. Photo and graphic by Mimi Broeske.

The coleoptile is pushed to the soil surface by the mesocotyl. When sunlight falls on the coleoptile tip, enzymes are activated that soften the tip allowing the first true leaf of the plant to break through. The growing point of corn is 3/4 of an inch below the soil surface and will remain below-ground until the plant has 5 to 6 leaves.

The germination process from dry seed to seedling emergence requires about 125 Growing Degree Units (GDUs). Normally in the beginning of May, we accumulate about 10 GDUs per day, so emergence takes about 12 to 13 days. The 2022 growing season is starting out fast with record high temperatures, and I have seen some recently planted fields already emerged. Emergence GDUs may need to be adjusted:

- If conservation tillage is implemented, add 30-60 GDUs.

- If planting date is before April 25, add 10-25 GDUs.

- If planting date is after May 15, subtract 50-70 GDUs

- If seeding depth is below 2 inches, add 15 GDUs for each inch below.

- If seed-bed condition has soil crusting or massive clods, add 30 GDUs.

- If seed-zone soil moisture is below optimum, add 30 GDUs.

There might be many reasons why a seedling does not emerge in a stand of corn. The germination process is really a race between pest pressure (diseases and insects) and the ability of the seedling to outgrow the pest. Seed treatments protect the seedling from disease and insects for the first 30 to 45 days of the growing season. Planting into cloddy/crusted or cold soils can result in seedling leaves unfurling below-ground, reducing plant stand and yield potential. Imbibitional chilling can result in plant death.

This one of my favorite times of the year in Wisconsin. I wonder what the growing season has in store for these developing plants. As you drive around the state, enjoy the landscape and all the different greens that develop over the month of May.

Saving Versus Earning for Seed Corn Inputs

I’m starting to get questions about costs this spring, which is not surprising given the recent COVID-19 effect on commodity prices. There are two significant components of the cost per acre equation: the number of trait technologies in the hybrid(s) a customer purchases and the plant population (which I’ll address at the end of this article).

Roundup Ready® hybrids cost roughly $30-/acre more than conventional hybrids (using 35,000 planting density and retail price for the technology, your mileage may vary). Most growers embrace the convenience of the technology and the “system” cost (trait + herbicide) is reasonable. Northern farmers (northern one half to two thirds of WI) have lower weed pressure and 70% of the time can use a single pre-plant or early post application of common tank mix herbicides where the system price is lower than the system price of Roundup Ready.

Corn borer protection, sometimes referred to as above ground insect protection, adds another ~ $20-/acre and is not available without the RR® trait in our lineup. Break even on this cost is a single corn borer in every plant (5% yield loss and $3-/bu) in 150 bu/acre corn. If yields or the commodity price increase, the number is more like one borer in every other plant. For growers in the I states (Illinois, Iowa and Indiana) plus Nebraska, it’s an easy decision: plant Bt corn.

Farmers in northern WI, MI, MN and the Dakotas will not likely see one borer per stalk where “not likely” is not the same as impossible. Growers in the southern one third of these states face a more difficult decision process and would generally be working right in the “break even” zone. Some considerations for these growers would include a scout and spray program probably costing the same as the trait technology, but used once every 5-7 years. Remember, the best spray program eliminates only two thirds of the pests which minimizes, not eliminates, damage. For the most northern growers, Renk Seed quietly has a “Dairy Dollars” program in Zone 3. Some Double PRO® hybrids are priced so the Bt portion of the trait fee is basically eliminated on the price list and can be purchased for virtually the same cost as RR products. This makes it an easy choice to have Bt on your farm (in Zone 3) and helps us with inventory management.

Corn rootworm technology (below ground protection) adds an additional ~$20-22/acre. When commodity prices were high, most growers planted fully traited hybrids for max protection which was our largest selling trait segment. VT2P® hybrids have been the largest selling trait segment for the past three seasons as farmers more carefully evaluate where they need to spend money. Rootworm beetle counts have been at historical lows the past two seasons and economic damage in wetter seasons would be hard to measure. On the other hand, there is no rescue treatment for corn rootworm, so the decision needs to be a sound one at the beginning of the season. If you need to control rootworm, the trait technology is the gold standard (review University of IL data). There are good soil-applied insecticide alternatives but are just as costly as the trait and less efficacious. There are numerous “cheap” insecticide alternatives in this space while, attractive from a cost perspective, deliver less than the price from a performance perspective.

Using an average trait technology mix, our customers spend ~$16- for 5000 kernels of seed corn – a great investment for the first 25-30,000 kernels/acre. Return per acre diminishes at some point and if you haven’t reviewed or updated where the density should be for your farm, current commodity prices and the hybrid you intend to plant, please do so before you go to the field. Honestly, most high-density recommendations are based on very high yielding research trials. If your farm doesn’t support high yields, get the density down where it makes sense. The following tables are copied from Extension publications from IL, WI and NE. I have included them so you can briefly review.

Summary Monmouth and DeKalb, IL data, two years (1990-91). Since this data is now 30 years old, I would increase the density response side of the graph by 5000 plants/acre.

Please remember that economic activity will return to normal, though I wish I could predict when. Consumers will have been cooped up for a prolonged period and I think there will be a rebound effect from pent up demand. Ideally this would occur before we get to harvest and the market starts reacting to supply. Another factor to consider when evaluating cost versus earnings is the possible price for this season’s crop, which has a good chance of being better than the virus-depressed price we are looking at going into planting.